The importance of infrastructure inspection and maintenance

Q: What is Infrastructure?

A: Infrastructure refers to the physical systems and resources essential for the functioning of society and the economy. It comprises public utility systems such as electricity and tap water, transportation and communication systems such as roads, bridges, and railways, as well as communication systems like telephones and the internet. It serves as the foundation that supports various activities, community expansion, and enhances people's quality of life. For our discussion, we will focus on the transportation sector of infrastructure.

Q: What is Infrastructure Inspection and Maintenance and why is it important?

A: As mentioned above, infrastructure serves as the foundation supporting various human activities. Therefore, it is extremely important to maintain infrastructure for efficient use while minimizing the impact on human activities. One thing we must understand is that all built structures, once completed and put into service, inevitably deteriorate with age and use. This deterioration can become severe, leading to structural damage, impacting service efficiency, and compromising public safety. Especially for infrastructure that has been in use for a long time, it is essential for various agencies to implement appropriate structural maintenance to ensure these structures can be used efficiently, safely, and to extend their service life.

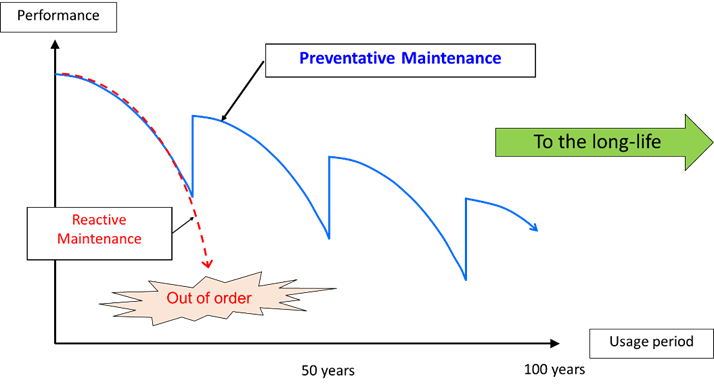

The graph above illustrates that when infrastructure is used without a planned inspection and maintenance strategy, undetected damage can lead to the structure becoming unusable.

This results in the service life of the structure ending prematurely, necessitating costly reconstruction or the replacement of structural components. This process requires the closure of traffic lanes or the entire road for several months to years.

In addition to the high construction costs, the resultant economic damage and public inconvenience are consequences that are similarly incalculable.

Q: What do other countries do?

A: Since we are a consulting company from Japan, let's start by discussing about Japan.

Japan is a country that experienced rapid economic growth. Between 1955 and 1975, Japan built more than 40% of its infrastructure. To illustrate this clearly, let's take bridges as an example. Currently, there are approximately 730,000 bridges in Japan. By 2026, more than 47% (or approximately 340,000 bridges) will be over 50 years old. Furthermore, by 2031, more than 50% (or approximately 365,000 bridges) will be over 50 years old.

Initially, Japan recognized the increasing age of its infrastructure. The Ministry of Land, Infrastructure, Transport and Tourism (MLIT) issued a guideline for infrastructure maintenance in 2004, titled: Notice of National Guideline for Periodic Bridge Inspection (for national road bridges), Prescribes specific inspection procedures. The MLIT established these guidelines to standardize periodic inspections for all roads and bridges under its jurisdiction.

However, this guideline was not yet mandatory, meaning some infrastructure, particularly that managed by municipalities and local communities, did not undergo inspection. The critical turning point that led Japan to legislate mandatory infrastructure maintenance was the collapse of the concrete ceiling panels in the Sasago Expressway Tunnel in 2012, which resulted in fatalities. The incident stemmed from damaged ceiling panel fasteners that had evaded proper inspection for over 35 years. This lack of oversight allowed the structural integrity to deteriorate until the ceiling panels eventually collapsed.

Subsequently, in 2014, the MLIT issued a law mandating the inspection of all Japanese infrastructure every 5 years. This was The Act for Partial Revision of the Road Act and Other Acts to Promote Maintenance and Longevity of Public Infrastructure. Since then, Japan has reviewed and revised its regulations in every inspection cycle, with revisions in 2019 and the latest version in 2024. The 2024 revision will be enforced for the third infrastructure inspection cycle between 2024 and 2028.

Q: Does Thailand have as much infrastructure as Japan?

A: Thailand also has a large amount of infrastructure.

- We have a total road length of approximately 707,000 kilometers.

- We have over 27,000 bridges under the care of the Department of Highways (DOH) and the Department of Rural Roads (DRR).

- This figure does not include community bridges under the supervision of Local Administrative Organizations (LAOs).

- We also have approximately 250 kilometers of elevated expressways.

Regarding bridge age, the clearest data available concerns bridges managed by the Department of Rural Roads (DRR), which has a total of 9,800 bridges. Over 50% of those bridges are older than 30 years. In our country, there are agencies and engineers who prioritize bridge inspection and maintenance. While expert professors and agencies have developed road and bridge inspection manuals, the lack of a formal legal mandate means that infrastructure inspection remains reactive. Consequently, agencies often only inspect structures after damage becomes visible.

Q: We have this much infrastructure. How can we inspect it all?

A: Think of infrastructure inspection like getting an annual health check-up.

Initially, your doctor doesn't immediately tell you to get a biopsy or any highly specialized, detailed examinations. We start with general checks of the body, such as weight, height, lung X-rays, or blood tests, to determine the preliminary condition of the body before proceeding with more detailed examinations based on the initial results or continuing with treatment.

Infrastructure inspection is the same. We do not conduct detailed inspections initially. We first carry out a general condition assessment of the structure before proceeding to detailed inspections and planning maintenance. Therefore, infrastructure inspection can be divided into the following inspection phases

| Inspector | Inspection frequency | Method | Remarks | |

| Routine inspection | Technician | 1 time / week | Visual inspection | -General condition (by patrol car or walk around) |

| Periodical inspection | Technician / Engineer | 1 time / 5 years | Visual inspection (Access closer as much as possible) | In some cases, use high efficiency equipment to support the inspection. |

| Special inspection | Technician / Engineer | As per necessary | Same as Periodical inspection and special inspection. | Damages occur in case of unexpected events such as earthquake, typhoon, heavy rain. |

| Detail inspection | Consultants | As per necessary | NDT, Analysis and calculation (as specify in periodical inspection result) |

It can be seen that the inspections in the first two phases—Routine Inspection and Periodical Inspection—do not take much time, are relatively easy to perform, and have low costs, so they can be initiated immediately.

However, due to the large number of bridges in Thailand, the responsible agencies can utilize the method of hiring private companies with sufficient knowledge and capacity to inspect and collect data for the bridges in the Periodical Inspection phase.

As for the inspections in the third and fourth phases, they require calculation, analysis, and determination of necessity and methods by expert engineers before they can proceed. These subsequent inspections are carried out to analyze and diagnose structural damage, including emergency inspections due to various disasters. These two latter phases demand higher specialization and more specific inspection methods, thus resulting in higher time consumption and costs.

Therefore, conducting the first two phases of inspection to collect data and assess the bridge conditions is highly important. Since these phases are quick and low-cost, starting the infrastructure inspection in the first two stages is definitely feasible.

Q: What can our company do?

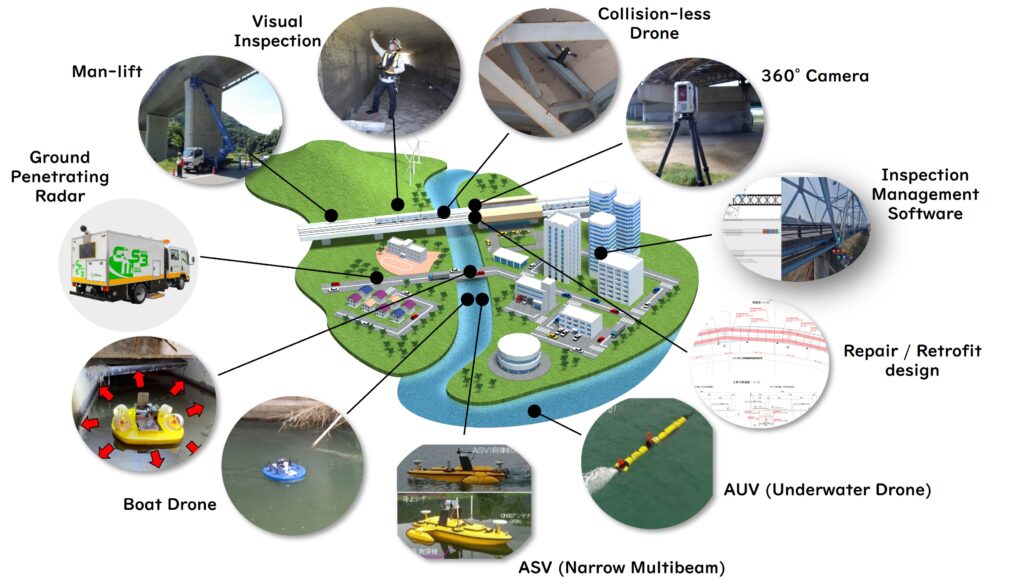

A: Our company is a leading firm in Japan capable of inspecting infrastructure, including roads, bridges, tunnels, reservoirs, and dams, across all inspection phases. This includes developing tailored inspection plans for each bridge and designing structural repairs.

The fundamental principle of structural inspection involves having experts survey critical areas, such as the area beneath bridge structures, the support between the bridge girder and the pier, bridge cables, and various bolted connections. It also includes surveying elements that are not visible to the naked eye, such as subterranean and submerged structures.

Our company is dedicated to developing various technologies to be used for inspection, substituting the need for experts to enter dangerous or inaccessible areas. Examples include using drones to fly to specific points and using underwater drones for submerged acoustic imaging.

Our scope of work aligns with the items listed below:

- Inspection and analysis of bridge conditions

- Inspection of Civil Infrastructure

- Preparation of inspection and maintenance plans

- Design of repair and strengthening works

- Application of digital technology/robotics/drones in inspection tasks

- Development of software and applications for database management

A key strength of our company is the careful selection of appropriate technology for each inspection phase and work condition. Crucially, the inspection technology is utilized by our own engineers, not by the equipment owners. Therefore, we obtain inspection results that precisely meet the engineers' needs while ensuring cost-effectiveness for the specific project.

Read more:

https://ejec-thailand.com/maintenance/

https://www.ejec.ej-hds.co.jp/en/service/